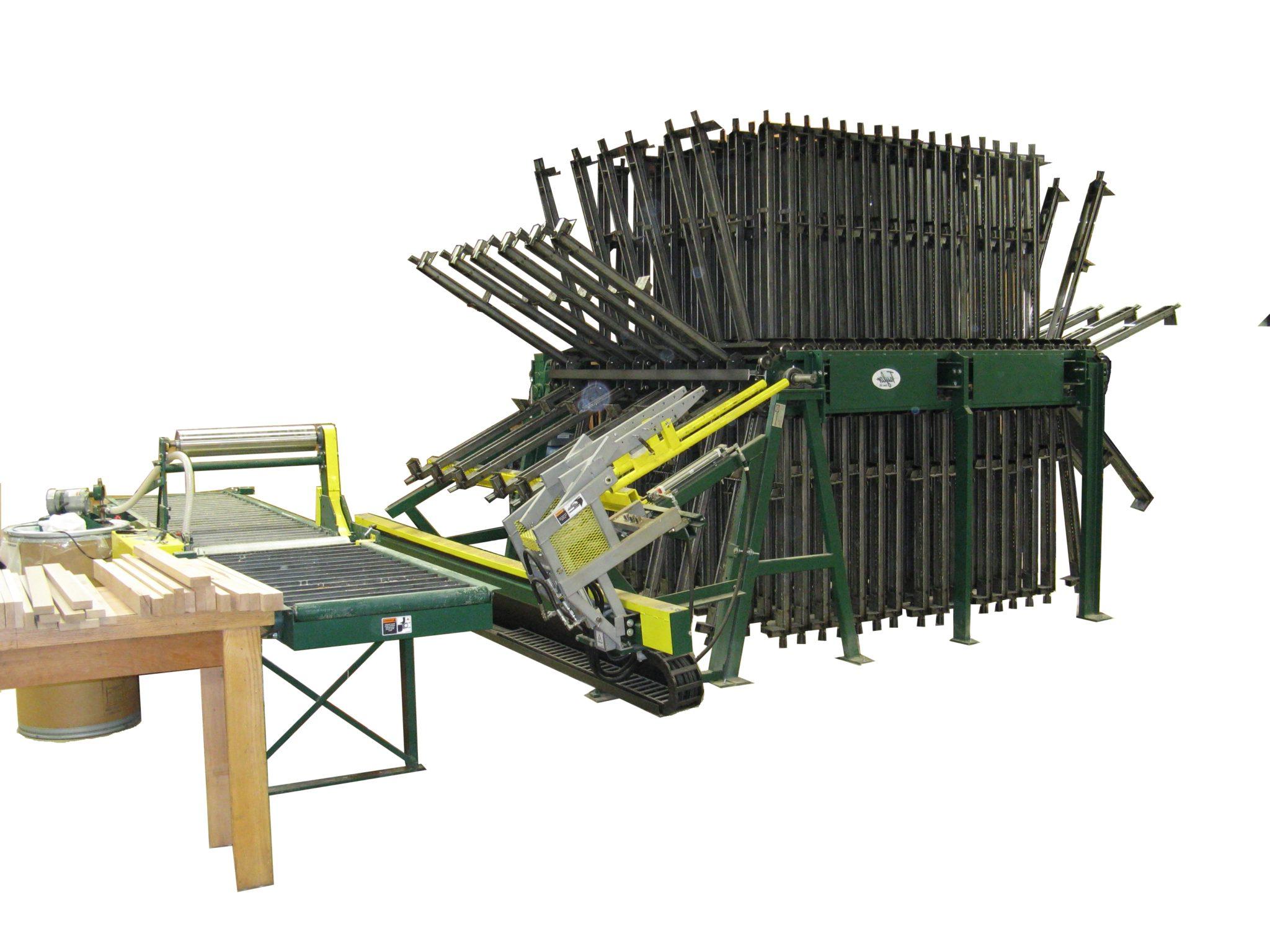

Features:

- (4) machine lengths return material up to 60″, 96″, 112″ long, or 132″ Long

- Heavy duty frame and component construction for long life (Heavier than the competition)

- Drop away receiving conveyor gently transfers parts to cross conveyor

- Photo-eye triggers drop of receiving conveyor. A PLC adjusts the timing automatically based on conveyor speed.

- 24″ or 36″ Rollers on return conveyors can handle up to 36″ or 50″ wide material.

- Optional 48″ Catch Rollers

- (Can be paired with a Powered Panel Turner for end banding longer panels up to 90″)

- Minimum material size 1″ x 6″

- Roller Spacing 3″ center to center

- All rollers are powered and individually clutched for long belt life.

- Any Length Return (in one foot increments, measured from tail end of shaper/sander) composed of modular sections.

- Return is 2 1/2″ lower than receiving conveyor, allowing for over/under return.

- Variable Speed AC drive matches conveyor feed rate to edge bander feed rate.

- Adjustable Height to match passline height of the Edgebander

The edge bander model comes in multiple widths and lengths. The outfeed return can be customized to return components to any location near the edge bander infeed. Numerous options are available for special applications.

(Additional Details and Info Below)